5 Axis Machining-Advanced Technology

Creative customers know what makes us tick: Quality, Promptness, and a long history in this industry. Our services include product design, engineering, prototyping, fabrication, precision machining, assembly, and inspection.

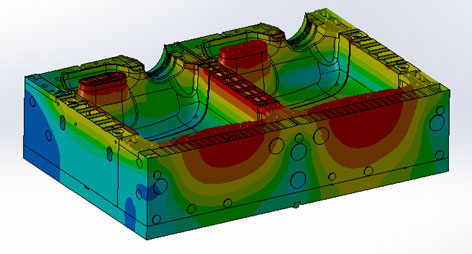

In the blow mold design process, Creative Blow Mold Tooling design engineers use Computational Fluid Dynamics (CFD) analysis to enable quick, efficient simulation of fluid flow and heat transfer. Our design engineers can easily calculate fluid forces and understand the impact of a liquid on product performance. In the above simulation, Creative engineers are able to identify in-advance, potential performance concerns. This process allows Creative to design our customers tooling right the first time.

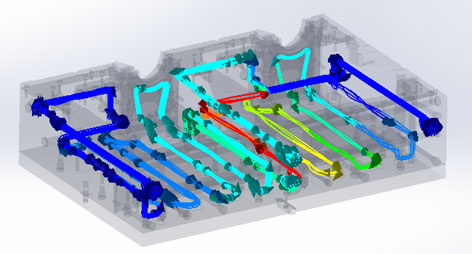

Creative recently added a Five Axis Haas UMC 750 machining center, expanding our manufacturing capacity; improving customer delivery timelines. This CAP X investment focuses on:

- A reduction of the number of set-ups and set-up time

- More efficient tool paths that reduce cycle time

- The ability to handle parts and processes that are more complex

- Expands Creative’s machining capabilities to beyond just mold manufacturing