From Idea to Superior Consumer Packaging

Quality is the first requirement in producing high-quality superior consumer packaging.

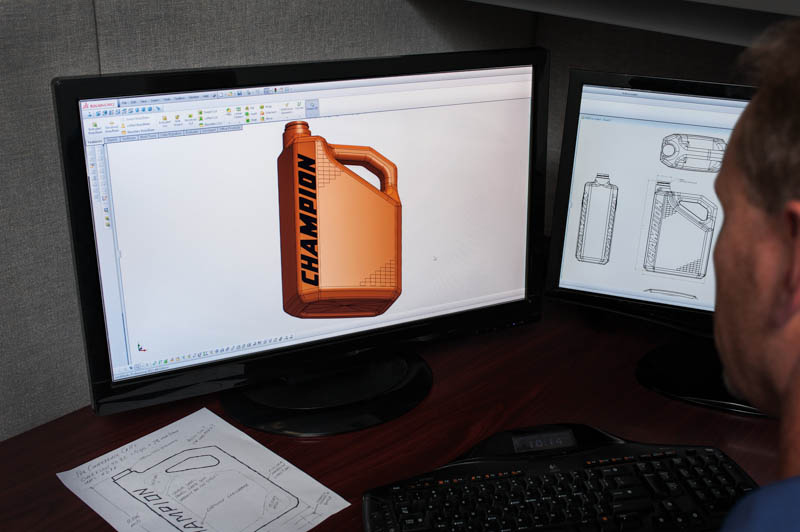

Being first to the marketplace means having an efficient supply-chain that shortens the timeframe from “Idea to Superior Consumer Packaging.” To shorten the supply-chain, Creative Blow Mold Tooling focuses on the initial package design. Our team of 5 full-time design engineers provides us with the ability to start immediately, taking your idea or paper drawing and generating a 3D computer design. No waiting!

With Creative’s 29 years of knowledge, a 3-D computer design is generated. This 3-D drawing of the new container can be reshaped, redefined, and modified to fit the desired new shape your customer wants and needs for the marketplace. This partnership with the Creative design team can dramatically reduce time to market, since this container can now be manufactured with our state-of-the-art computerized manufacturing, compressing your supply-chain timeframe.

Once the customer has approved the 3D computer drawing, seeing how the actual container will appear on the shelf is an important step. Using technologically advanced additive manufacturing methods like “3D printing,” layers of resin or plastic create a durable, highly accurate physical model of the new container. Your customer can quickly see, feel, and handle the container for a final approval process, allowing one more look at the container design prior to mold manufacture.

With this final approval process completed, the approved 3-D computer designed model is sent to the programming department, creating the CNC programs needed for each machine to manufacture this new mold for mass production.

In our operations, we couple upfront design efficiencies with lean manufacturing techniques to maximize throughput that generates an effective value stream and reduces lead times. Results: A high-quality precision mold. This allows Creative to meet demanding customer-scheduled deadlines. Production of a Superior Consumer Package.