Experience, Technology & Precision

State-of-the-art equipment coupled with knowledgeable design, engineering and manufacturing assures the optimal outcome for you. We continually improve our processes and upgrade our equipment, incorporating the latest technological developments. In fact, Creative has used advancements in our facility’s technology to reduce the cost of new blow molds significantly over the last ten years. This technology along with our engineering and manufacturing competence assures the cost effectiveness of Creative’s finished products. Consequently, customers benefit from highly competitive pricing for top quality molds.

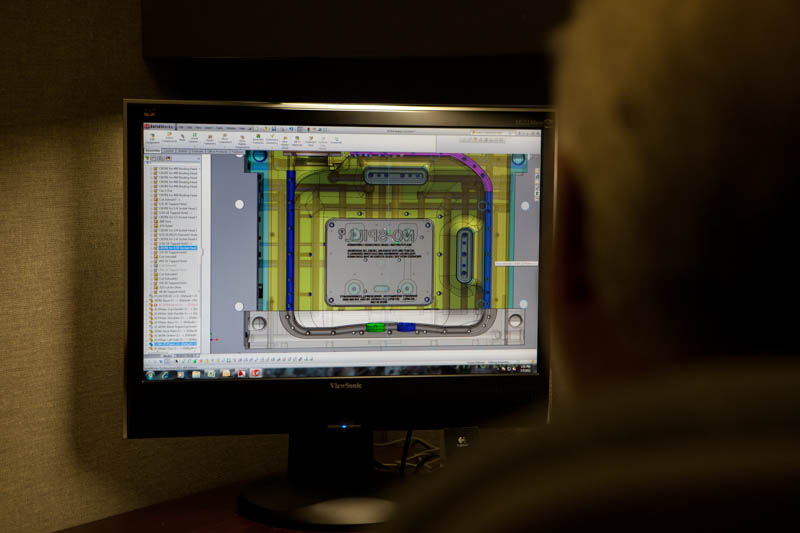

Design Tools

Our design staff works with several different CAD/CAM programs (SolidWorks, AutoCAD, Pro/Engineer, and Mastercam) and can import files from several different formats. A Renishaw Cycle Digitizer (wtih Tracecut software) is also used by the design engineers.

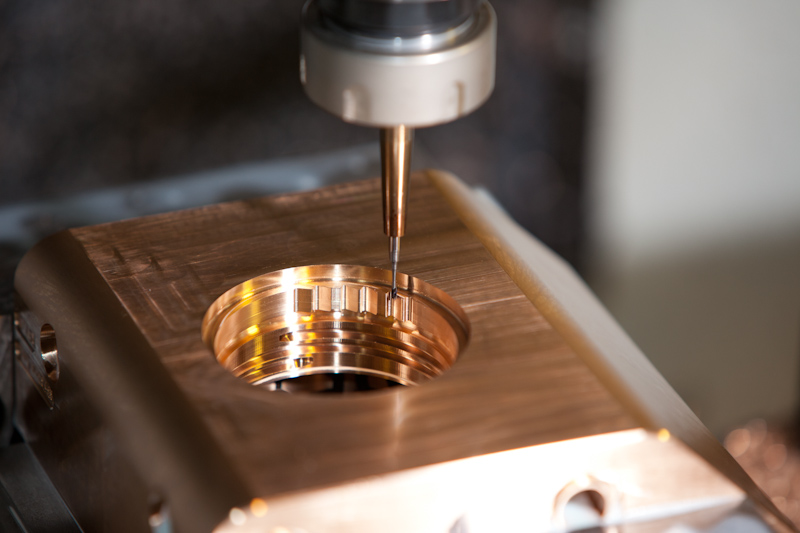

Manufacturing

Our recently expanded shop includes 17 pieces of CNC equipment: eleven vertical machining centers, four horizontal machining centers, and two lathes. We also have an assortment of manual milling machines, grinders, and a turning center.

In-Process Inspection

All work is inspected and documented as it comes off each work center and our quality control department assists with all first-part inspections as well as final inspection documentation

Quality Lab

Quality control equipment includes optical comparators, water pressure checking systems, a CMM, and multiple pieces of inspection equipment.